El Toro Pro – distributator issues but signs of promise

Didn’t have a chance to attend to the car in the week between the SD National Tour and the El Toro Pro Solo, but did manage to get the Friday off.

Arrived at El Toro around 10am Friday and got to work on the car.

The ignition system had been acting funny at the Tour, and I decided to replace all of it – the distributor, the coil, and the ignition switch, with new but identical components.

Since the car wasn’t yet running, replaced them all with it still in the trailer, which was fine for the stuff in the engine bay, but a pain to do the ignition switch – had to climb in then contort myself around and under the dash without opening the doors, to get the switch out.

Even with those replaced things weren’t quite right, and it wouldn’t be until late the next day, I’d realize it was because one of the main wiring harness plugs from the engine bay to the firewall, wasn’t snapped in all the way.

But Friday evening the car was starting and running, and while I missed out on practice starts, did get a chance to make a couple planned suspension adjustments to address the handling.

First was lowering the rear roll center.

In the pic you can see there are 12 “holes” in which one can place the pivot bolt for the watts. In the interest of not having an understeering car, I’d started at hole #8 (bottom being #1, top being #12, keeping in mind this photo shows it upside-down). Not knowing how big a difference this would make, I lowered it as far as I could, to hole #2. Holes are 1/2″ apart, making that a change of rear roll center height from ~13″ to ~10″.

The second change was to a stiffer front swaybar-

This is part of why I like modular sway bars so much – for not much $, can shift the adjustment range upwards. On the right is the old .188″ wall bar, on the left is the new solid unit, about 20% stiffer.

Saturday morning the car started fine, took off for my first run – handling felt much improved! Unfortunately, halfway through the run, the car cut out, then sputtered for a couple seconds, then shut off. Was able to coast most of the way to the finish, and some helpful folks assisted in getting it pushed to the broken car area near impound.

Hood went up and the work began, probably 11:30am.

The fuse for the ignition circuit had blown. I replaced it with a larger fuse, and it blew instantly. Hmmm.

Removed everything from the ignition circuit except for the wire to the distributor, and removed the wires from the distributor to the coil – instant blown fuse. Hmmm.

Multimeter shows near zero resistance in the distributor (the brand new one put in the day before) – fried/shorted distributor. D’oh!

Swap in the suspected bad distributor from the day before – it’s not working either. Try swapping to previous coil just in case, nope.

A kind fellow from C2 Motorsports has been helping me for hours but now has to go.

It’s now about 2:00pm.

Head to local Pep Boys, they have a couple decent high-performance distributors for a small block chevy. If it had been 1983 or 1993 instead of 2013 I probably would have had a lot more options but they had a decent looking Accel unit.

Get back to the site and work to get it put in. This one is HEI so the “head” of the distributor is bigger around – after a lot of effort I get it seated, but…it is so big, it only goes in one way, and there’s no way to “clock” it to get the initial timing where it needs to be. A little searching reveals the common mod done alongside an HEI distributor install “hammer the firewall” – not an option here.

Back to Pep Boys to return the Accel. The only other option now is OE replacement stuff. They don’t have a high-performance Z/28 dual-points distributor but they do have the single-point unit for a standard 327 or 350. It’ll have to do. I try to be thorough and be sure to leave with a new cap, rotor, and even an extra set of points.

Back at the site (probably 5:30 now), go about installing the OE stuff. Get the cap on and…duhhh, my spark plug wires aren’t going to work with this cap! The OE points-style cap is female, the wires I’d made were for a male HEI-style cap.

With the sun sinking lower in the sky, and even the worst possible ignition option still a long way off, this is probably the low point of the weekend.

At this point someone I don’t know approaches and jokes, in a great southern drawl, “I hear you got a prob’m with yer distributater?”

Just like the weekend before, the Solo community again helped me get through a tough spot, this time with a laugh.

In a desperate move to avoid the inevitable, gave the Mallory distributor used at the SD Tour another try – nope, it didn’t magically fix itself.

About 6:45pm now.

So back to Pep Boys yet again (this was actually trip #4 that day, since I stopped by on my way up for some detailing products) – this time for spark plug wires and a crimping tool. Had these things at home, but that was far away and it was still a little light out.

Back to the site before sundown, get the points distributor in and cap on. I notice there’s a little window on the side of the cap that can slide open – I ask Gary Thomason what it’s for – “it’s for adjusting the dwell”. DWELL?!?!?! Oh man, like I have the tools, much less the know-how, to adjust dwell. This junk is going to have to run as it came out of the box.

Around 8:30pm as I’m trying to make spark plug wires on the passenger seat of the truck by its crummy interior light, Thomason suggests it might be easier to make them at home. With the El Toro gate closing at 10pm, figure there’s no way I’m getting it running tonight, and decide he’s right.

Once at home, with a nice ratcheting crimper and good lights, I get the wires made and get to sleep by 11:30pm.

Up at 4:30 and back to the site by 6:05am-

Not happy about having left the car out overnight, but not much choice.

Get to work installing the newly made spark plug wires, which are all way too long. Then it’s time to get initial timing set, which takes a while. The distributor is geared off the crankshaft, but it is also keyed to the oil pump, but I eventually work out a technique, not having my oil pump rotation tool, to rotate it to allow for moving the distributor around till the timing is close. Along the way the car starts and runs (poorly) with 90 degrees of advance!

Steve O’Blenes comes by and saves my butt for the second weekend in a row, making the coil tower wire (which I forgot needed an HEI style plug at one end) and helps me get the engine idling and timed with his fancy test kit (since I now have no tach signal from this distributor).

Eventually I get it around to 20 degrees of initial advance which it likes a lot, and leave it there. Free-revving up high with the vacuum detatched and plugged, it looks to advance to 37 total, which should be ok.

So I drive it back to my regular paddock spot, probably 9:30am now, cars have started running.

Thomason is checking rear toe on his Viper…since he’s got the equipment handy we check front toe on the Camaro. I’d eyeballed it as “toed out” but never measured properly.

1″ out! Oops.

With some STX cars already headed to grid I jack up each front corner and toe them in a bit. Not very scientific in the amount but it should be closer. Steering link threads are very coarse.

Car is a little finicky to start but eventually it does, and make it to grid in time. On the way there, steering feels much more normal now with toe settings slightly less ridiculous.

Leave it idling, lest it be snotty and not want to restart. A few things combine to make starting difficult – some of it is all the ignition advance it wants. Another is when the car’s been run a while, the headers heat-soak the starter, making it more difficult to turn. When it’s really hot, the fuel in the carb and lines gets hot too.

Eventually we get our chance to run. Starting on the right side, and pretty much right away I experience the “natural rev limiter” brought on by the points ignition. It feels like it starts sputtering by 5000rpm (about 48mph) and wouldn’t rev at all over 55-5600. Can’t really tell without the tach. Low and midrange felt softer too.

At least I got a run in!

Left side went a little bit better – video here (158MB):

First left-side run at El Toro Pro Solo

I was going light on the throttle in the high rpm sections (which was most of the course), not sure what the ignition issue might be doing to the engine. With a little heat in the tires and the rubber-coated surface of a clean Sunday morning ProSolo course, the grip felt great. In the middle of the turnaround the thought, “Oh $#%! Hope that oil pan is doing its job!” popped in my head – the car was actually cornering well – and on exit it got even better! Could use practically full throttle on the way out. Granted I may have been down 50-100hp but it felt great! It was still loose on entry and a bit sloppy-loose in transitions, but wow, what an improvement!

Second right side run I tried going to third gear in two spots to keep the car accelerating above its sucky 55-ish terminal velocity. With the close-ratio 4 speed the car actually accelerated well in third, but with basically zero experience shifting this car in any situation and no good feel for where each gear is, the downshifts were awkward, and the car seemed extra-loose transitionally without the second gear engine braking. Still managed to drop time with an awful run.

Last run on the left side had a horrible light and launch, but I pushed the car a little harder and decided to keep it floored in second gear even as it kept popping and sputtering at high RPM. Stupid points would be coming out right after this anyway. The run was going really well – a little brake-induced oopsie into the turnaround, and a little hot into the slalom, but then it all went to pieces in the right-hander afterwards (142MB):

Second left-side run at El Toro Pro Solo

In looking at the data from that run, it would have been about a second faster than the first, taking away the horrible launch and up until the spin. I didn’t countersteer as far as I could in the spin’s initial slide, after damaging one of my upper control arms (which will necessitate replacement of one of the SPC arm’s segments) saving a spin at the SD Tour.

In impound the car drew quite a crowd. Why now?! I was so embarrassed by the ugly blue spark plug wires strewn all about, most 2′ too long, held in with ugly untrimmed zip ties. Oh well.

Since I worked so hard on the car I’m giving myself a temporary pardon from the crime of stacking excuses and woulda-coulda-shoulda’s, so – if you figure that could have been a mid-high 50.x run, and it was only my second complete lap on that side, things look pretty good. The leaders were mostly in the 50’s in their first couple runs on that side Saturday morning. I’m still quite a ways from having the handling sorted, and the car was *way* down on power, which actually did have a cost on this course, even if it did maybe make it easier to drive. Plus my own driving isn’t that good, still a bit rusty, and need time to adapt to a car.

I feel strongly that this car, at full power, with the handling better sorted, current-generation tires, and me driving well (not to mention getting all 6 tries at each course!), would have been competitive at this event.

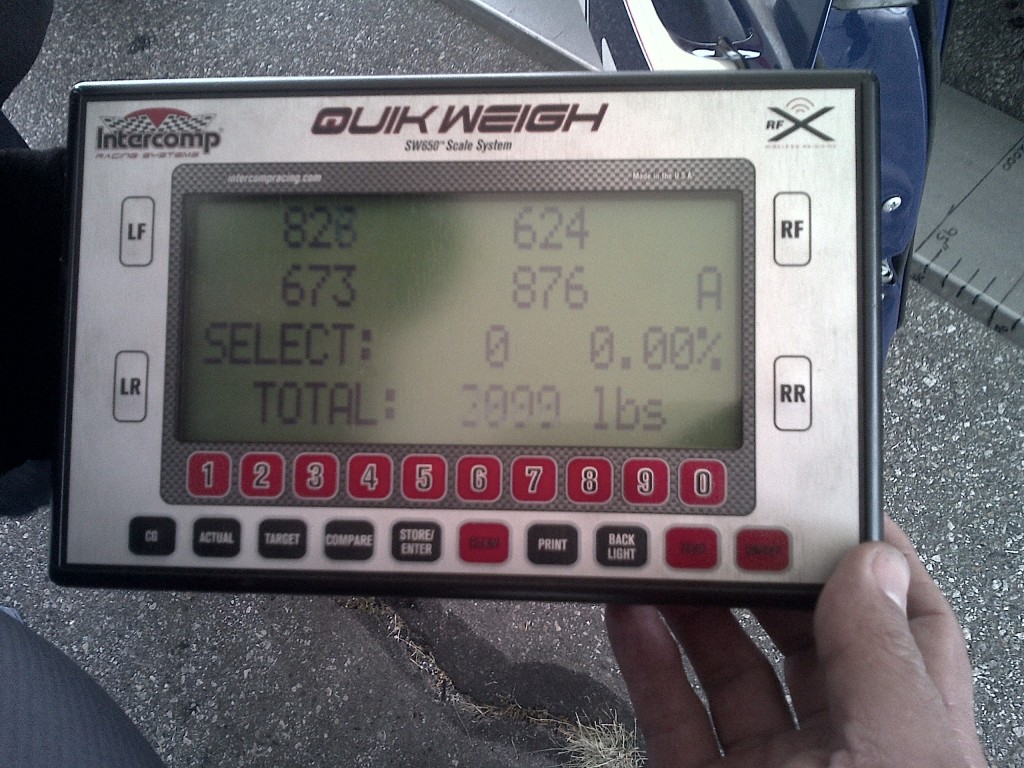

Oh, one final bit of optimism – got the car on the scales after my runs. While the below looks like a corner-balancing shop’s dream, in reality the scales had just come back from being under the Berry’s broken SM Evo, and weren’t put back in the right places – so, the 8xx weights are fronts, 6xxs are rears. The scale location isn’t leveled so corner weights would be way off anyway, but f/r and total should be right.

Total was flickering between 2999 and 3000 – yay! That is 9-10 pounds lighter than I’d estimated (3009) based on published curb weights and component part weight deltas. More nose-heavy than I’d like but I’ll take that over being heavy everywhere.

Pretty much the only weight the car could lose from here is in the back – the lighter battery could be about 35lbs. saved, and if the car can be run lower on fuel, that could be a lot, depending on how much lower. It was completely full for Saturday morning (18 gallon tank) so it probably still had 15-16 gallons in it at time of measure. If it were like a Viper or Corvette that could run down to just a few drops in the tank, this thing could see a potential Nationals race weight of 3000 – 35 (battery) – (14 gal x 6.25 lb/gal = 87.5lbs) = 2877lbs. Of course it isn’t, and conventional wisdom says you have to run a full tank in these things, so it’s not likely to ever get anywhere near 2900 in competition.

Compared to my old STS 240sx, this is about 130lbs. heavier at each front corner, but only about 40lbs. heavier on each rear corner.

Still, I’m pleased with the result, and this answers one of the big questions from early on in the build. Seen staunch estimates from people convinced it would weigh 2700lbs, and others convinced there’s no way it could get below 3300. As often happens, the truth lied somewhere in the middle… 🙂

Great story!!

I was wondering about the weight, and it seems about right, maybe a little lighter than I thought it was going to be.

Points ignitions are reliable as dirt, and great for lawn mowers. Those of us who grew up with them feel your pain. A long time ago, there actually was a high performance version of the standard Delco points that had a higher spring rate. Or if you were poor like me as a teenager, you could cut an extra set apart and install two springs in one set of points. It made the rubbing block wear like crazy, but with leaded gas the plugs needed cleaning every couple of weeks anyway if you wanted to rev it high.

I don’t recall exactly what you are limited by the rules, but if you must run points, dwell is IMPORTANT! It can make a huge difference. That Pep Boys distributor also probably has an advance curve way to slow for your engine.

There is no reason to keep the tank full. That big holley has the effect of a surge tank. You are running a block mounted mechanical pump aren’t you? You will not have a fuel starvation problem on an autocross unless you have almost nothing in the tank.

The hot start issue has been around forever, but I have only ever had 1 car afflicted by it. Changed the starter and solenoid and it was never a problem again. You may want to swap yours, or look into the gear reduction starters. They are smaller, lighter, and supposedly immune to the heat soak issue.

Keep the updates coming, and make the video files smaller if you can. I cant download a 150+MB file.